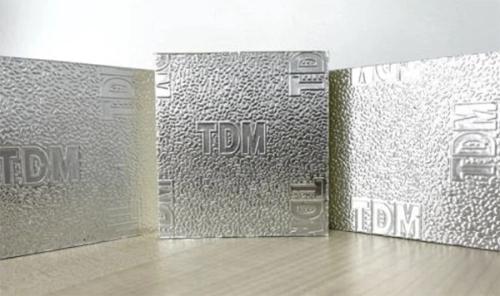

TDM Panel

Product Characteristic

TDM Pre-insulated aluminium duct is developed as an alternative to the conventional ducting system. It is a sandwiched panel made of PIR (POLYISOCYANURATE) foam covered in smooth or embossed 80 micron aluminium foil (anti-mould & anti bacterial coated) . Nice in aesthetic, doesn't rust, non fibrous, zero permeability, anti mold and anti bacteria, contain no HCFC, lower air leakage, doesn't absorb moisture and fast installation speed.

All pre-fabrication work can be done before sending to the site, reduce wastages and much lesser workers needed at site . It is silent in operation at site.

TDM duct is very light weight, 6 times lighter than G.I. duct with insulation . This significantly reduced building load, roofing load and ceiling load. Also it uses less hanger , less labour and faster installation time. Suitable for commercial office buidings,factories and malls.

- Maximum pressure in duct is up to 2,000 Pascal or 8” WG.

- Can be used for AHU connection due to its high rigidity. Can be easily dismentle and re-assemble back for cleaning, maintenance or modification purposes.

- Thermal conductivity is 0.022 W/m°C with no mechanical joins on the longitudinal duct section. Therefore is thermally better and very minimal leakage compare to conventional duct system.

- Nice aesthetic for expose type ducting and can be covered with paint to suit architectural purposes.

Product Specification

| Thickness of panel | 20mm |

|---|---|

| Density of panel | 50 +/- 2 Kg/m3 |

| Thermal Conductivity | 0.022 W/m°C |

| Compressive Strength | 200 N/mm2 |

| Weight | 1.5 Kg/m2 |

| Working Temperature | -60°C to +80°C |

| Pressure max. in duct | 2,000 Pa ( 8 inch WG ) |

| Air flow max in duct | 12 m/s |